Our range for the defence industry includes a wide selection of speciality chemical products and innovative cable management systems. Due to the specific operating conditions of military technology equipment, it is essential that these products can withstand adverse atmospheric factors such as extreme, fluctuating temperatures, from very low to very high, UV radiation, as well as other external variables such as electromagnetic fields, vibration and mechanical impacts. Resistance to the effects of aggressive chemicals, from fuels through lubricants and oils to disinfectants, is also crucial. The products we offer for the defence industry comply with strict norms and standards, guaranteeing the highest quality and appropriate technical parameters. The most well-known and recognised include the US MIL / MS (Military Standard), now taken over by the SAE association and labelled AS (Aerospace Standard), and the German VG (VerteidigungsGeräte-Normen).

Recommended products for the defence industry

Lubricants for aerospace

Our product range for the aerospace industry consists of universal and specialised lubricants from ROCOL, as well as anti-corrosion agents for all metals exposed to adverse operating conditions. ROCOL is the undisputed leader in the production of lubricants used in the aviation industry. The AEROSPEC series we offer is a range of top-quality aviation lubricants, from multi-purpose greases for airframe, landing gear, power unit and actuator components, to specialised anti-seize pastes and anti-corrosion sprays. ROCOL AEROSPEC lubricants are designed for both commercial and military aviation and approved for use in rotorcrafts and fixed-wing aircrafts.

Stainless steel cable ties

Products used in the shipbuilding industry must be resistant to changing and adverse atmospheric conditions and have high mechanical strength. In our shop, we offer, among others, stainless steel cable ties with a fold locking of the HellermannTyton AMT series, ideally suited for marine applications. These cable ties have been specifically designed for use in extremely harsh environments. Made from acid-resistant type 316 stainless steel, they are characterised by their high corrosion resistance, high temperature resistance and resistance to the effects of seawater and chemicals, making them ideal for use on ships and offshore platforms. They are resistant to vibration thanks to the folding mechanism, which ensures that the ties are tightly and firmly fastened, even in areas subject to high vibration. The stainless steel cable ties are suitable for very heavy loads (up to 2,500 N), making them also widely used in the rail and construction industries.

High temperature adhesives

In the military industry, resistance to high temperatures is crucial. One of the products we recommend is ELASTOSIL E14 silicone adhesive from Wacker. It is a one-component silicone rubber sealant with an acetoxy curing system and a convenient non-sag paste consistency. It has excellent resistance to high temperatures (long-term up to +200ºC) and good vibration resistance. It is mainly used for bonding and sealing heating elements and all other components operating at high temperatures and exposed to vibration, i.e. standard conditions in the defence industry.

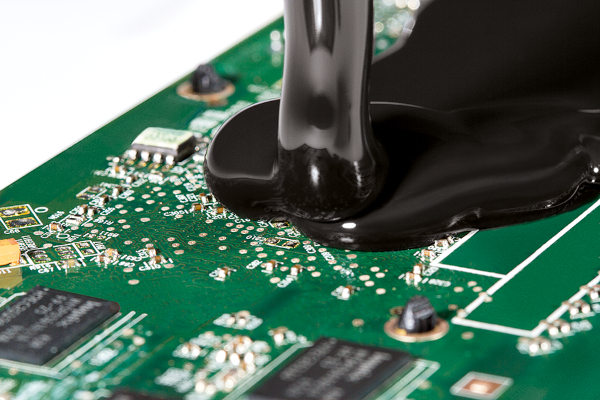

Epoxy potting compound for military electronics

Electronics used in the military industry are exposed to extreme and adverse environmental conditions and therefore require durable products to insulate and protect them. For the encapsulation of electronic and electrical circuits in military applications, we recommend ResinTech's epoxy potting compounds such as RT355. This two-component, fast-curing, thixotropic epoxy resin is characterised by its excellent adhesion to flexible substrates. It effortlessly bonds metals, glass, wood, rubber and many plastics. Supplied in DuoSyringe for easy application, the RT355 fast setting potting compound is highly resistant to fluctuating temperatures, shock and oils.

Heat shrink tubing DR25

Another recommended product is the DR25 heat shrinkable tubing from TE Connectivity. DR25 is a series of flexible, self-extinguishing, abrasion-resistant heat shrink tubing. They are primarily designed for the insulation and mechanical protection of electrical harnesses and cables in the defence industry, including military vehicles. They are characterised by their high resistance to extreme temperatures and aggressive chemicals such as aviation fuels, diesel, hydraulic fluids and lubricating oils. Thanks to their optimal properties, DR25 heat shrink tubing is also popularly used in the automotive, rail and aerospace industries, as well as in motorsports.

Heat shrink moulded shapes

Heat shrink moulded shapes are one of the components of the so-called heat shrink technology for making harnesses for military applications. They are used to protect the connection of the harness to the electrical connector and the branching of electrical harnesses. They protect the electric cables from mechanical stress, preventing them from being pulled out of the connection, and also, with the use of a suitable adhesive, ensure the tightness of the entire bundle. Heat shrink moulded shapes in conjunction with the heat shrink tubing protect the electrical harness mechanically (against abrasion, excessive bending, and impacts), thermally and against the ingress of moisture.

Shielding sleeves

An important issue in military equipment is to ensure electromagnetic protection at an appropriate level. Shielding copper braids are used to protect cable harnesses. To prevent oxidation, the copper fibres are coated with tin or, in a high-temperature version, nickel. There is a choice of protective sleeves made according to US MIL-SPEC standard AA59569 (formerly QQB575) or German VG 96936 T10.

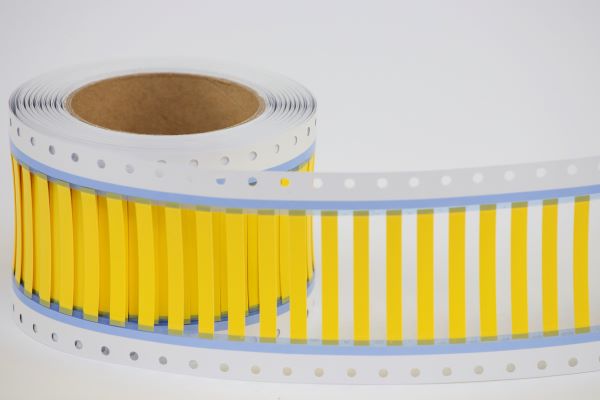

Heat shrink markers

Completing the military cable harness are heat shrink markers. The marking is applied using a thermal transfer printer. Ladder-style shrinkable markers made from flame-retardant polyolefin are most commonly used in the defence industry. However, high-temperature, halogen-free and diesel-resistant heat shrink markers are also available. Continuous heat shrink tubing for printing is also available, for use in the production of heat shrink markers, usually of unusual length or in small batches.