The right silicone adhesive for your needs!

The silicone adhesive from Wacker Chemie is ideal for bonding silicone, metal, glass and ceramics.

Are you looking for an adhesive for the flexible bonding of silicone, metal, ceramics and glass? Silicone adhesive is the best solution. Silicone has excellent adhesion to many different materials without the need for primers (surface activators). Such materials include, in particular, glass, ceramics and aluminium. Silicone adhesive is also practically the only adhesive suitable for silicone (also known as silicone rubber). Silicone adhesive provides an elastic joint, which is required when the bonded materials move in relation to each other. This can include both static and dynamic stresses. Silicone adhesive, thanks to its flexibility, offsets these, which is why it is widely used where vibrations and stresses occur and when bonding materials with two different coefficients of thermal expansion.

RTV-1 and RTV-2 silicones, which are used to produce silicone adhesives and silicone potting compounds, also have very high-temperature resistance. Standard silicone adhesive is resistant to temperatures up to 150oC in continuous operation, and high-temperature silicone, i.e. silicone adhesive with special additives, up to 250-275oC. High-temperature silicone adhesive can work at higher temperatures, but it should be remembered that working at temperatures above 250oC causes slow destruction of the material, which results in an increase in hardness and a decrease in the elasticity of the silicone adhesive.

Silicone adhesive RTV-1

RTV-1 silicone adhesives are one-component silicone compounds that cure at room temperature from exposure to air humidity. During curing, they release a residual product in the form of a vapour, usually with a characteristic odour. Depending on the type of vapour released, silicone adhesives are classified into three groups:

- Acidic silicone adhesive, emitting acetic acid vapour

- Amine silicone adhesive, emitting amine compounds

- Neutral silicone adhesive, emitting either oxides (oxime) or ethanol or methanol vapour (alkoxy)

The release of residual product during curing causes RTV-1 silicone adhesives to have a shrinkage equal to the amount of residual product released. Typically, the shrinkage of RTV-1 silicone adhesive is in the range of 3-5%.

RTV-1 silicone adhesives are characterised by very good adhesion to the substrate and convenience of use. The disadvantage, however, is the rather long curing time (full curing is usually about 12h/mm), dependent on air humidity (min. 50%).

Silicone adhesive RTV-2

Silicone adhesives RTV-2 are two-component silicone compounds that cure at room temperature or elevated temperatures. They are divided into condensation silicones, which have a shrinkage of 1.5-2%, and addition silicones, which have a shrinkage of approximately 0.1%. Condensation silicones are compounds where the curing speed is controlled by adding the correct amount of hardener or by using a hardener with lower or higher reactivity. The most common application of condensation silicones is as a silicone potting compound for electronics and electrical engineering. Sometimes they are also used as a high-temperature silicone adhesive for high-volume production.

Addition silicones, on the other hand, are more modern compounds whose curing is controlled both chemically with a catalyst (accelerating the reaction) and an inhibitor ( slowing down the reaction), as well as by increasing or decreasing the temperature from room temperature level, i.e. 23oC. The most common applications of addition silicones are as a potting compound for electronics, as a gel for potting electronics, and as a fast-curing silicone adhesive.

Examples of silicone adhesives RTV-1 by Wacker Chemie

ELASTOSIL E43 Wacker Chemie – the best transparent silicone adhesive on the market

A single-component, transparent silicone adhesive with a thick, self-levelling consistency and excellent mechanical properties (acidic curing system). The adhesive cures at room temperature and forms an elastic joint.

Application:

The adhesive is used for bonding silicone (silicone rubber) to various materials and components subjected to vibration or high temperatures up to 150oC. It can also be used to seal housings and joints. Due to the release of acetic acid vapour during curing, the product is not recommended for use in contact with copper.

ELASTOSIL N199 Wacker Chemie – the best neutral, transparent silicone adhesive on the market

Neutral, transparent, single-component silicone adhesive with paste consistency and excellent mechanical properties (oxime curing system). The adhesive cures at room temperature and forms an elastic joint with distinguished tensile strength.

Application:

The adhesive is used for bonding heavier components on electronic boards, corrosion-sensitive components, components subject to vibration and silicone rubber. It can also be used for sealing housings and joints, and mounting solar panels into frames.

ELASTOSIL E14 Wacker Chemie – high-temperature silicone adhesive

One-component high-temperature silicone of paste consistency (acidic curing system). The adhesive cures at room temperature and forms an elastic bond with good mechanical properties. Thanks to special additives (iron oxide), the silicone adhesive is red and can work continuously at 250-275oC.

Application:

High-temperature adhesive for glass and metal.

Examples of silicone adhesives RTV-2 by Wacker Chemie

SEMICOSIL 989/1K Wacker Chemie – transparent, fast-curing silicone adhesive

Neutral, transparent, single-component silicone adhesive of paste consistency with excellent mechanical properties. The two components of the adhesive are pre-combined and the curing is initiated by elevated temperature. The adhesive cures even in a few minutes depending on the temperature and forms an elastic bond with very good tensile strength.

Application:

This product is used as a high-temperature silicone for bonding glass metal and other materials exposed to vibration or high temperatures. Due to its high price, it is only used where RTV-1 silicone adhesives have a too-long curing time, unacceptable for technological reasons.

Other silicone products from Wacker Chemie

In addition to silicone adhesives, our product range also includes silicone compounds for other applications. A large part of our product range is made up of chemicals for bonding, sealing and coating electronics, e.g. silicone resin for bonding electronics, silicone thermal conductive paste, thin-film so-called conformal coating, silicone potting compound for electronics, silicone electro-insulating paste, silicone gel for bonding electronics, and others.

Examples of silicone potting compounds for coating electronics

ELASTOSIL N10

One-component silicone rubber for the thin-layer coating of electronics (oxime system). The product is a neutral mass with good adhesion to most materials, which cures at room temperature, giving a transparent, highly elastic coating. The coating can be easily removed locally using a sharp tool, e.g. for repair or replacement purposes.

Application:

Elastosil N10 is used for thin-layer coating of electronics to protect against moisture, rapid temperature changes, corrosive vapours, mechanical damages and shocks. The product is also used as a silicone adhesive and sealant for electronic and electrical systems that are particularly exposed to vibrations.

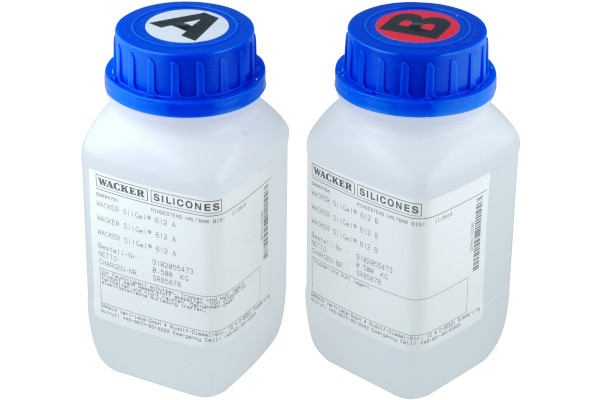

SilGel 612 A/B

Liquid, two-component silicone potting compound for electronics with high softness after curing. This silicone gel has high transparency and very good adhesion to the substrate. Thanks to its low viscosity, silicone potting compound penetrates into highly integrated electronic circuits. The product also has a very low shrinkage on curing of 0.1 % and, due to its very low hardness, does not create stress during curing. This potting compound for electronics is suitable for colouring with colour pastes FL.

Application:

This product is used for protecting electronics against moisture, particularly optoelectronic systems and highly sensitive electronics. It is also used to protect electronics against vibration, particularly electronics used in transport. Furthermore, it is a silicone potting compound for power modules, rain and pressure sensors, and a silicone potting compound for photovoltaic modules. The product is also used to seal filters for high-purity rooms.

ELASTOSIL RT 607 A/B

Two-component high-temperature silicone potting compound. This potting compound for electronics has enhanced thermal conductivity (0.55 W/m-K) and low shrinkage during curing (0.1%).

Application:

This silicone potting compound for electronics is used to protect electronics against moisture and vibration. It is particularly used in power electronics, mining equipment, temperature sensors and for potting electromagnets operating in steel plants.

Silicone pastes

Paste P

Multi-purpose silicone electrical insulating paste with good migration stability. It is resistant to high temperatures and does not affect the properties of plastics and rubber.

Application:

- protection of electronics against moisture

- electrical insulation

- vibration damping,

- distributor (release agent)

- assembly support (reduces friction, especially when assembling rubber and plastics)

- sealing

Paste P12

Thermally conductive silicone paste with good migration stability even at high temperatures.

Application:

A product that facilitates the conduction of heat used in the assembly of power circuits and power electronics components to heat sinks. Particularly recommended for operating temperatures above 100°C.