Flexible conduits are an excellent protection for electrical cables.

Plastic conduits

Halogen-free and self-extinguishing HelaGuard plastic conduits are used especially where there is a need for a tight, lightweight and flexible conduit for electrical cables with good corrosion resistance. Conduits can be made from different plastics that have different properties. The standard material used for industrial conduits is polyamide 6 (PA6). This material is used to manufacture flexible cable conduits in the thin-walled version - HG-LW, the standard version - HG-SW and the thick-walled version - HG-HW. These versions differ primarily in their crushing strength and flexibility.

The good mechanical properties, flexibility, abrasion resistance and flexural strength of non-metallic conduits, as well as high resistance to UV radiation, oils and chemicals, meet the basic requirements of manufacturers of industrial machinery and equipment.

Plastic conduits with special properties

Flame retardant conduits meeting the highest class of flame retardancy of plastics - UL94 V0 - HG-FR, and conduits for dynamic applications made of polyamide 12 (PA12) - HG-HI are used in the rail industry and public utility buildings. Thanks to their flexibility, they are suitable for installations in continuous motion and can therefore be used in robotics, railway and other such machinery and equipment.

Conduits are available in a wide range of sizes, with outer diameters ranging from 10 to 67 mm (inner diameter 6 to 56 mm), naturally with matching fittings.

Double slit plastic conduits

To facilitate installation, we also offer double slit corrugated conduits made of PA6 - HG-DC, which allow installation in control panels or machines on already connected cables. This type of corrugated tubing is constructed as two pipes, one smaller, and the other larger, with appropriately designed slots. In addition to the slot, the smaller pipe also has a notch on the opposite side of the slot which, when inserted into the larger pipe, fits perfectly into and covers the slot of the larger pipe. Thanks to this design, double slit conduits use the same fittings as full-profile corrugated conduits.

Fittings for plastic conduits - straight external thread

HelaGaurd plastic conduits are matched with technically advanced fittings that guarantee the highest quality connection to the conduit. The one-piece fittings provide excellent tensile strength and are assembled quickly and simply by pushing them onto the end of a conduit of the correct size. All HG fittings comply with IP66, while for particularly demanding requirements there are HGL fittings, which provide IP68 and IP69k protection. Fittings are available with metric and PG threads, as well as UNEF and NPT threads. To facilitate bolting, HellermannTyton provides fittings with swivel internal and external threads made of brass.

Fittings for plastic conduits - special fittings

The variety of fittings is enormous. The range of fittings includes, in addition to straight fittings, 45° and 90° elbow fittings, flange fittings, and T- and Y-shaped fittings. An interesting solution is couplers and reducers, which allow conduits of the same or different diameters to be connected.

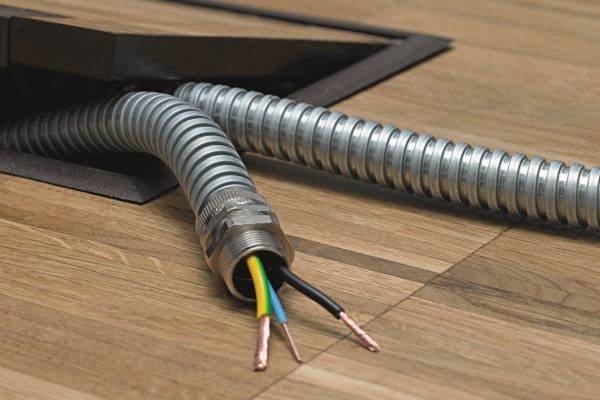

Metallic conduits

Flexible steel conduits are made from a profiled sheet of galvanised steel, which is precisely twisted so that the individual coils connect properly to each other, ensuring that the conduit has the right tensile and torsional strength as well as good flexibility. It should be noted that the flexible steel conduits of this design are not watertight.

For applications in aggressive environments, we offer conduits made of acid-resistant stainless steel. Stainless steel conduit is constructed identically to galvanised steel conduit, the only difference is in the material.

Fittings for metallic conduits

For steel conduits, we offer suitable fittings to ensure a tight and reliable hold of conduit. Threaded fittings provide excellent tensile strength, preventing the conduit from being pulled out. The basic material for the fittings is nickel-plated brass. For conduits made of stainless steel, we also offer fittings made of acid-resistant stainless steel.

Metallic conduits with liquid-tight cover

To ensure the tightness of corrugated steel pipes, they are coated with plastic. The primary material that is used to coat flexible steel conduits is PVC (conduits of the PCS series). It must be taken into account that both the thickness of the coating affects the flexibility of the steel conduit as well as the flexibility of the coating material. As PVC is a moderately flexible plastic, more flexible materials such as polyolefin (LFHCS series conduits - halogen-free with low gas and smoke emissions when burning) or thermoplastic rubber (LTSH series conduits) are used for areas with higher flexibility requirements. Similarly, for higher temperatures, steel conduits coated with either polyamide PA6 (NCS series conduits up to 120°C) or thermoplastic rubber (LTSH series conduits up to 150°C) are used.

Metallic conduits with metallic overbraid

For additional protection against abrasion, conduits with a galvanised steel overbraid are used. In addition to extra mechanical protection, the steel overbraid also provides good protection against hot steel splatter (e.g. in steelworks, foundries and during welding), as well as very good electromagnetic protection. Available are both bare steel conduits with a galvanised steel braid (conduits of the SCSB series), as well as steel conduits with a plastic coating and an additional protective braid made of galvanised steel (conduits of the PCSB series).

Fittings for metallic conduits with liquid-tight cover

As with steel conduits, we offer suitable fittings for steel conduits with liquid-tight cover to ensure that the conduits are securely fastened. The threaded fittings provide excellent tensile strength, preventing the conduit from being pulled out. The primary material for conduit fittings is again nickel-plated brass. It should be noted that full IP68 water tightness can only be achieved with LTS series conduits (flexible, waterproof steel conduits with PVC coating) or LTSH series conduits (flexible, waterproof steel conduits with thermoplastic rubber coating) and LTS series fittings.

Flexible spiral-reinforced conduits

Another type of conduit for electrical cables is conduits made of soft PVC, reinforced with a steel spiral (FlexiGuard series) or a spiral made of hard PVC (PSR series). Conduits of this type are more flexible than conduits made from PA6 polyamide, and more resistant to aggressive chemicals.

Conduits of the PSRSC series are made smooth both internally, which makes it easier to insert the conductors, and externally, which makes them easier to clean. This is why they are most commonly used in the food and pharmaceutical industries, where high cleanliness is important.

Fittings for spiral-reinforced conduits

Fittings for spiral-reinforced conduits can be made of plastic (IP54, IP65 or IP67 depending on the type of conduit) or metal. Metal fittings are made of either nickel-plated brass or stainless steel and are designed for PSRSC series conduits, providing IP68 and IP69k sealing.