Thermal transfer printer is the best solution for industrial identification printing

A thermal transfer printer takes advantage of the benefits of thermal transfer printing technology to offer good print quality, high speed and the ability to permanently apply markers to a wide variety of materials. Thermal transfer printing also provides good legibility and chemical and abrasion resistance, which allows the thermal transfer printer to be used in applications where the results of laser, dot matrix or inkjet printing are unsatisfactory. For these reasons, thermal transfer printers are increasingly used for marking in industry and beyond.

Advantages of a thermal transfer printer at a glance:

- High print quality with a resolution of 300 dpi

- High printing speed: from 30 mm/s to 150 mm/s

- Printing of standard barcodes and 2D barcodes

- Printing of any monochrome graphics

- Easy and quick printing of self-designed markers

- Quiet operation and easy handling of the thermal transfer printer

- The thermal transfer print is high-contrast and well-reproduced

- The thermal transfer print has high mechanical, chemical and UV resistance

How does the thermal transfer printer work?

For a thermal transfer printer to work properly, in addition to the printer itself, you will need the material on which you will be applying the markings, a thermal transfer ribbon and software for designing your markings and managing the printer.

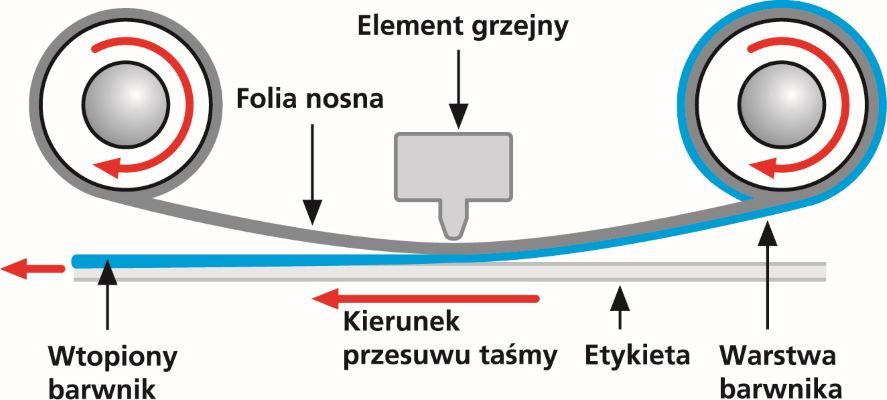

A thermal transfer ribbon is a thin polyester film coated on one side with a dye which changes its state of matter from solid to liquid under the influence of high temperature. Based on the main dye component, thermal transfer ribbons can be classified as wax ribbons, resin ribbons and wax-resin ribbons. Wax ribbons, due to the low melting temperature of the dye, are characterised by ease of overprinting (they can be used at very high speeds and low printing temperatures), but the durability of the overprint is relatively low. These thermal transfer ribbons are most often used for printing on paper labels (e.g. logistics labels, tickets), which usually have a short lifespan. Resin ribbons, on the other hand, require very high temperatures and long heat-up times. In return, they offer excellent print resistance to abrasion and aggressive chemicals. This type of thermal transfer ribbon is used for industrial marking. The final group, wax-resin ribbons, are a combination of the characteristics of the two previously mentioned types of thermal transfer ribbons.

The main component of a thermal transfer printer is the thermal transfer print head. This is a high-precision electronic component comprising a huge number of microheaters arranged in a line. A thermal transfer print head with a resolution of 300 dpi has 12 microheaters on a length of 1 mm. In addition to the thermal transfer print head, the printer also has a ribbon and material feed mechanism and a control system for print head heating and feed speed.

The thermal transfer printer transfers the dye on the thermal transfer ribbon, heated by the thermal transfer print head to liquid form, onto the marking material, e.g. a self-adhesive label. The thermal transfer printer ensures that, in addition to the correct temperature generated by the thermal transfer print head at the appropriate points, optimum pressure is applied to the thermal transfer ribbon on the marking material.

A thermal transfer printer can usually work as a thermal printer. In this case, no thermal transfer ribbon is used, but a thermosensitive marking material, such as thermal paper, is required.

Thermal transfer printer - types and accessories for thermal transfer printers

There is a whole range of different thermal transfer printers on the market. These can be divided into portable thermal transfer printers, i.e. those suitable for use on the marking site, and desktop printers, which are most often used on production lines.

Depending on the strength of the design, a distinction can be made between standard thermal transfer printers and industrial thermal transfer printers.

Portable thermal transfer printer

The hand-held thermal transfer printer is usually a small, handy portable device with a keyboard. It usually allows for simple, quick alphanumeric markings to be made on the spot. Some hand-held thermal transfer printers offer the option of more complex marking, e.g. graphic symbols and barcodes.

Desktop thermal transfer printer

Desktop thermal transfer printers are usually designed for higher print volumes, and the design of the markers and management of the thermal transfer printer is usually carried out using special software from a connected computer. The desktop thermal transfer printer is usually equipped with a thermal transfer print head with a width of 100 mm, which allows printing on various flat materials such as self-adhesive labels, heat shrink tubing, markers and identification plates. There are also special printers available, e.g. dedicated to textiles.

Thermal transfer printer for double-sided printing

A thermal transfer printer usually allows single-sided printing. However, a thermal transfer printer for double-sided printing has been developed especially for marking heat shrink markers. Such a thermal transfer printer is effectively a double thermal transfer printer, as it has two thermal transfer print heads, one at the top and one at the bottom. Printing takes place first in one print head, then in the other print head.

Accessories for thermal transfer printers

In addition to printing on a variety of materials, a thermal transfer printer can also perform certain other functions such as cutting or perforating. These functions are particularly useful when using continuous materials in roll form. With the cutter, it is possible to make a full cut to the specified length after printing, while with the perforator, it is possible to perforate the material, which the user then tears just before assembly. The perforation function is very useful when making cable markers from heat shrink tubing.

Thermal transfer printer - consumables

Thermal transfer printers are designed to print flat materials. Therefore, the materials to be printed should be suitably flattened and their surface should ensure good dye adhesion.

Adhesive labels for thermal transfer printers

Self-adhesive labels for thermal transfer printing are the primary material for a thermal transfer printer. Adhesive labels made from polyester film, which is relatively cheap and durable, are most commonly used and ideal for marking flat surfaces. However, due to their relatively high rigidity, self-adhesive labels made from vinyl film, which is much more flexible, should be used for uneven so-called structured or rounded surfaces. If you want to produce so-called flag-style cable markers, you should also use self-adhesive labels made from vinyl film.

Panel plate labels for thermal transfer printers

The new type of self-adhesive labels introduced recently are panel plate labels. These are thick self-adhesive labels made using a thick layer of special, peel-resistant adhesive. These types of self-adhesive labels successfully replace engraved plates in terms of aesthetics and offer a much lower cost and much greater convenience and speed of production.

Adhesive self-laminating labels for thermal transfer printers

A special category of self-adhesive labels is self-laminating labels. Self-adhesive labels of this type are made of a soft material, usually vinyl film, which is non-transparent in part and transparent in the other part. The non-transparent part forms the printable area, on which the marking is applied, while the correspondingly long transparent part (protective laminate), much longer than the circumference of the electrical cable, is glued onto the descriptive field during assembly. In this way, self-laminating labels as cable markers adhere tightly and grip very well to the electrical cable being marked. At the same time, applying the transparent end of the label to the marking field provides additional protection for the marking against abrasion and other external influences.

Heat shrink tubing for thermal transfer printers

The second most commonly used material in a thermal transfer printer is heat shrink tubing. This type of marking is used as an increasingly popular cable marker. Heat shrink tubing for thermal transfer printing is specially flattened and its surface suitably degreased, so that the dye from the ribbon can easily adhere to the material. Standard heat shrink tubing, halogen-free heat shrink tubing, diesel-resistant heat shrink tubing or temperature-resistant heat shrink tubing are all available for printing in the thermal transfer printer. Heat shrink tubing is usually supplied in continuous form. With the aid of accessories, the thermal transfer printer can cut or perforate the heat shrink tubing into cable markers of a specific length.

Heat shrink markers for thermal transfer printers

In addition to the continuous form, heat shrink tubing for thermal transfer printing can be supplied as pre-cut heat shrink markers of a specific length, prepared for printing in ladder-style form. This form of heat-shrinkable marker makes it easier to find the right marking, which reduces assembly time. It also optimises print head usage and ribbon consumption.

Identification plates and tags for thermal transfer printers

Identification plates and tags are adhesive-free labels. Just like heat shrink tubing, they can be made as standard, halogen-free, diesel-resistant and heat-resistant. They are usually attached as cable markers to bundles of cables or wires with large cross-sections using cable ties.

One of the materials available is polyurethane. Using a special colour ribbon containing a solvent, the dye applied with a thermal transfer printer penetrates the structure of the material. This creates a so-called tattoo effect, making the marking practically indelible, even when exposed to aggressive chemicals.

Thermal transfer printer - printing service for individual identification systems

Although the cost of a thermal transfer printer is getting lower and lower, the professional marking needs of some customers are so small that it is not worth it for them to invest in a thermal transfer printer. For such customers, we have launched a personalised identification printing service. We can help you choose the right material for your application. We design the markings according to the customer's specifications and then print the labels using an industrial thermal transfer printer. With the appropriate functions provided by the software for designing and automating printing, we can provide our customers with any marking. Self-adhesive labels or cable markers can include alphanumeric characters, standard barcodes, 2D barcodes (e.g. QR Code), and any graphic symbol (e.g. company logo).