Properly selected cable markers make it easy to label cables and wires.

Cable marking is now much easier than before. There is a variety of cable markers available to customers, which, on the one hand, makes it easier to accurately select the right cable marker for one's needs, but on the other hand, makes it necessary for users to delve into the details of how one cable marker differs from another. The following information should make the choice easier.

Pre-printed slide-on cable markers

Slide-on cable markers are made as closed profile bushings with a preprinted letter, number or symbol marking. The profile of the cable marker bushing can be round or oval or suitably shaped to provide resilient pressure on the cable. Cable markers of this type require access to the end of the cable or wire, which means that they can only be installed prior to connecting or inserting the connector. Slide-on cable markers can have a straight cut, i.e. have straight sides, or they can have a chevron cut, i.e. have uneven sides which mesh with other markers. The second solution ensures that the cable markers do not twist in relation to each other on the electrical cables.

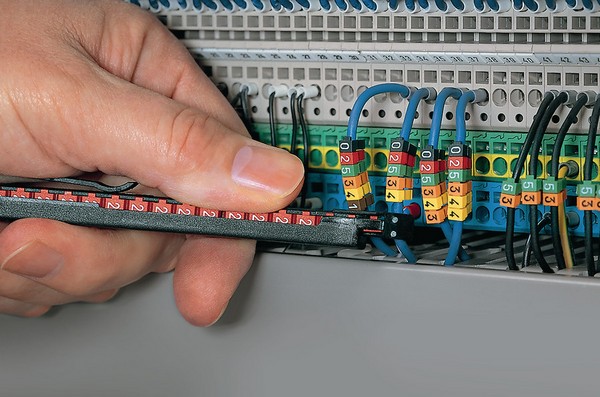

Pre-printed snap-on cable markers

Where the cables are already connected and we cannot disconnect them, cable marking is carried out using snap-on cable markers. These are open-profile cable markers with a gripping system, which allows them to be properly secured on the cable or wire. They also lock together to give perfect text alignment. Snap-on cable markers are easy to use and vibration-resistant.

Self-laminating labels

A rather interesting way of labelling cables is with special adhesive labels consisting of a non-transparent part (the printable area) and a transparent part (the protective laminate). When applying such an adhesive label to a circular element like a cable, we apply the transparent protective film onto the description field, thus protecting the description from the effects of moisture, aggressive chemicals and abrasion. Please note that the self-laminating label must have a properly selected length for the diameter of the cable.

Self-laminating labels are available for manual marking (in pocket-sized booklets or convenient dispensers), for printing in classic laser printers (in A4 format) or dot matrix printers (with perforation on the edges), and the most professional version for printing in thermal transfer printers (in rolls).

Thermal transfer printer

One of the most popular methods of creating cable markers today is thermal transfer printing. A thermal transfer printer works by transferring the dye from the ribbon to the material by spot heating. With this technology, we can mark heat shrink tubing, adhesive labels, identification tags, cable markers, and more.

Cable markers printed by the thermal transfer printer can include alphanumeric characters, graphic symbols, bitmaps, barcodes and 2D barcodes.

Thermal transfer printers can be hand-held or desktop and can be adapted for small print volumes as well as for industrial use.

Heat shrink markers

The most popular material for cable markers is heat shrink tubing. Heat shrink markers are produced based on heat shrinkable tubing with a specified wall thickness, prepared for printing in a thermal transfer printer. In particular, the heat shrink tubing is flattened and its surface degreased to ensure the best possible adhesion of the thermally transferred dye.

The heat shrink cable markers can be fed to the thermal transfer printer in continuous form (the heat shrink tubing is fed directly from the roll) or ladder form (the heat shrink tubing is cut to the appropriate length and applied to the carrier tape in ladder form).

Heat shrink marker material supplied as a continuous tube

Cutting or perforating the continuous heat shrink tubing creates the heat shrink cable markers. This operation can be carried out automatically during printing. For this purpose, the thermal transfer printer must have an automatic cutter or perforator.

Depending on the type of material, a distinction is made between standard heat shrink tubing, halogen-free heat shrink tubing, heat resistant heat shrink tubing, diesel-resistant heat shrink tubing and certified heat shrink tubing, for example, for use in the rail, aerospace or defence industries.

Ladder-style heat shrink markers

Ladder-style shrinkable markers are made from heat shrink tubing cut into lengths of e.g. 50 mm (they can also be perforated once or twice in the middle to form 25 mm and 16 mm markers respectively) and applied parallel to each other on the carrier tape so that it resembles a ladder.

Just like continuous heat shrink tubing, ladder-style printable heat shrink markers are also available in a variety of materials. Standard, halogen-free, heat-resistant and diesel-resistant heat shrink markers are available, as well as certified heat shrink markers, for example, for use in the rail, aviation or defence industries.

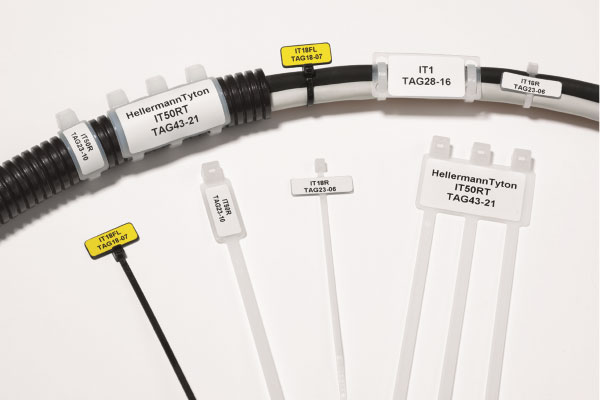

Identification tags for cable bundles

Identification tags are adhesive-free cable markers designed to be fixed using cable ties. Their main application is the marking of components with larger diameters, in particular the marking of electric cables, cable bundles, hydraulic hoses, as well as the marking of pneumatic hoses.

Similarly to printable heat shrink tubing (heat shrink cable markers), the identification tags are also available in a variety of materials and can be used as markers for cables and wires operating in various conditions.

Stainless steel cable markers

The marking of cables operating in very harsh conditions is based on metal cable markers, usually made from acid-resistant steel. These can be supplied as embossed markers or as carriers into which pre-embossed markers with selected symbols are inserted. In both cases, the markers are usually fixed with stainless steel cable ties.

Other cable markers

In addition to ready-made cable markers, other identification systems are also used to label wires and cables. One of the systems is identification ties, which are plastic cable ties with an identification plate, on which labels can be hand-written or adhesive labels printed using a thermal transfer printer can be applied.

A second type of product used as cable markers is plastic identification plates and tags attached by cable ties or rivets. Similar to identification ties, the description is done either by hand or by applying specially tailored self-adhesive labels printed in a thermal transfer printer.

Cable ties with RFID Transponder

One of the latest methods of marking are RFID (Radio Frequency IDentification) tags. They are based on a miniature electronic circuit together with an antenna enclosed in a sealed housing. The radio reader sends out a radio wave at the appropriate frequency, which powers the tag and triggers it to respond. The tag responds by sending its unique identification number (UID).

Cable ties with an integrated RFID tag are used to mark wires, cables and cable harnesses, as well as other circular items such as pipes, and hoses, among others.