Cable ties and cable clips have no secrets from us.

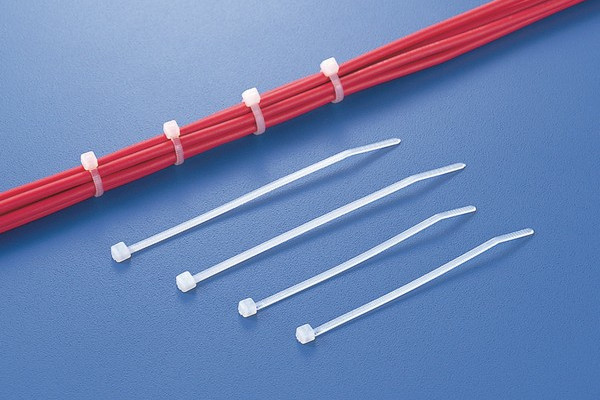

It would seem that cable ties are not very complicated products. A cable tie consists of a cable strap, usually serrated, and a head integrated into the strap with a locking pawl inside. Thanks to the high tensile strength of the loop created with a closed cable tie, the cable tie provides the ability to bind bundles of wires, cables or other components securely, as well as attach them to structural components. However, both the design of cable ties and the materials used in their production result in cable ties being available in a very large number of types to suit a wide variety of applications. Different materials allow cable ties to achieve a variety of properties, e.g. resistance to UV radiation, high or low temperatures, aggressive environments, etc. The use of cable ties, made from a material suitable for the operating conditions, significantly extends their service life.

The same is true of the design of cable ties. Externally serrated cable ties protect the insulation of the cables being bundled, releasable cable ties allow the same cable tie to be repeatedly fastened and unfastened, and fixing cable ties allow a bundle of cables to be bundled and secured to various structural components at the same time.

Therefore, the use of suitable cable ties for bundling and fixing wires and cables significantly simplifies and speeds up installation time. It also increases the quality of performance and extends the product's failure-free service life.

Plastic cable ties

Technological progress has made it possible to use plastics in practically every area of our lives. The main advantages of plastic are the ease of shaping, the speed of production and, of course, the price of the material. Standard cable ties are also mainly made of plastic.

Standard plastic cable ties

The primary material from which cable ties are made is polyamide 6.6, also known as nylon 6.6. This plastic is flexible as well as tensile resistant. Nylon cable ties with inside serration are currently the most widely used and applied plastic cable ties in the world. Many manufacturers offer cable ties of this type, competing with each other only by price. However, it is important to realise that the lowering of the price is reflected in the quality of the relevant materials and therefore in the properties of the cable ties offered. The most common visible effect of the use of cheaper granules or the use of recycled secondary granules is the high hardness and breakage of cable ties.

Premium plastic cable ties

In more demanding applications such as batch production, where every second of the assembly process counts, poor quality or instability in the quality of the cable ties cannot be tolerated. For such applications, cable ties made from high-quality granules are available. The primary material is still polyamide 6.6, or nylon 6.6, but of much higher quality.

UV-resistant cable ties

It should be noted that, like most plastics, nylon 6.6 is not UV resistant. This means that cable ties made from natural nylon 6.6 are not resistant to weather conditions and cannot be used outdoors or exposed to sunlight. To ensure that the cable ties are UV-resistant, carbon black is added to the granulate in an amount of at least 2%. This causes the cable ties to be black in colour.

Attention!!! Not every cable tie in black is UV-resistant. For colouring polyamide 6.6 cable ties black, carbon black is also used, but in a much lower percentage.

Cable ties with increased temperature resistance

In addition to cable ties made from polyamide 6.6 and weather-resistant polyamide 6.6, the use of heat stabilised cable ties, i.e. with increased temperature resistance, is very common. These cable ties are made from nylon 6.6 with a special additive, which allows the cable ties to work continuously at temperatures of up to 105°C.

Cable ties with open head

HellermannTyton has launched the Q series open head cable tie system to enable a simple and quick installation. This is a system based on cable ties with a specific head design, which allows the tie to be fastened by inserting the thin part of the cable tie into the open lock head. This speeds up installation time by 25%. In addition, the Q-series cable tie offers a pre-locking function, which allows a temporary cable fastening solution. This function is achieved when the tail of the cable tie is inserted into the open head and pushed partly into the head.

Releasable cable ties

Cable ties are usually single-use cable ties. However, there are reusable cable ties that allow repeated fastening and unfastening. Although they are more expensive and their tensile strength is lower than that of disposable cable ties, they are used in applications where temporary binding, locking or fixing is required.

Plastic cable ties of special design

Cable ties can have a special design to accommodate special tasks. One of the most commonly used designs today is cable ties with an outside serrated cable strap. These types of cable ties have a smooth inner surface of the cable strap and are mainly used in areas where standard cable ties with inside serration would damage the insulation of the wires or cables being bundled. These are primarily used for cable harnesses exposed to vibration (automotive and rolling stock industries) or with insulation made from delicate materials such as halogen-free or silicone insulation.

Cable Ties without serration (smooth on both sides)

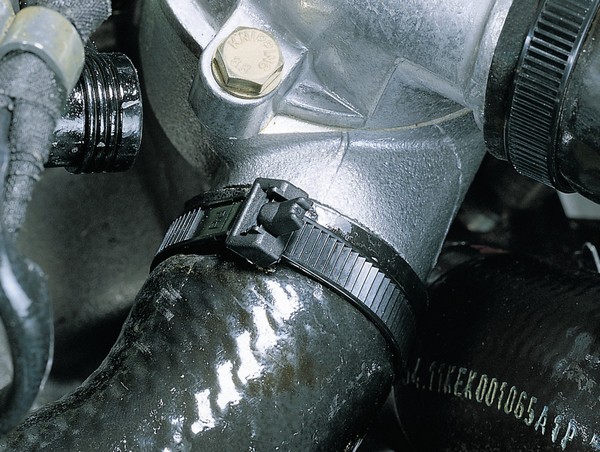

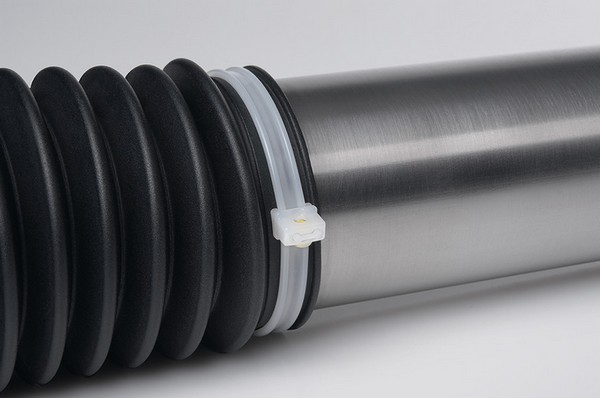

Another type of cable ties with a special design are cable ties without serration. This type of cable tie has a special locking mechanism equipped with a locking pin, which is pressed into the cable strap. Cable ties with this locking mechanism are insensitive to vibration and have a higher tensile strength than standard ties of the same width. In addition, thanks to their design, they adhere very well to round components and are widely used as hose clamps for sealing hoses and flexible pipes, e.g. water pipes.

Heat-resistant cable ties

Although the primary material used to manufacture cable ties is polyamide 6.6, there are other, more specialised materials from which cable ties are made. One such material is polyamide 4.6, which has a much higher heat resistance than polyamide 6.6. It is therefore recommended that cable ties that will operate at temperatures of up to 150°C are made from this material.

Cable ties resistant to high temperatures, aggressive chemicals and radiation

Another special material used for the production of cable ties is Ethylene/Tetrafluoroethylene (ETFE), also known by the trade name Tefzel. It is a material that not only has excellent heat resistance (up to 170°C), but also resistance to very low temperatures (-80°C). In addition, cable ties and cable fixing elements made from E/TFE have excellent resistance to aggressive chemicals as well as to radiation and UV radiation. For this reason, they are used in the chemical, petrochemical, food and pharmaceutical industries as well as in wastewater treatment plants, medical equipment and nuclear power plants.

Cable ties resistant to aggressive chemicals

A much cheaper material that is resistant to aggressive chemicals is polypropylene. Furthermore, polypropylene is one of the few plastics that floats on water. For this reason, cable ties made of polypropylene are used in the chemical, food and pharmaceutical industries and in sewage treatment plants. However, it must be remembered that cable ties made from polypropylene have approximately half the tensile strength of those made from polyamide 6.6.

Cable ties resistant to high temperatures, aggressive chemicals and radiation

One of the newest materials used for cable ties and cable fixing elements is PEEK (polyether ether ketone). It has an excellent operating temperature range of -55°C to 240°C and low thermal expansion. These characteristics make PEEK cable ties and cable fixings very popular in the aviation industry. In addition, PEEK is resistant to radiation and UV radiation, as well as to aggressive chemicals.

Detectable plastic cable ties

Recently, plastic cable ties detectable by metal detectors have become very popular. They are made from polyamide 6.6 with the addition of metal particles. Due to their properties, cable ties of this type are dedicated to the food and pharmaceutical industries.

Metal cable ties

In addition to plastic cable ties, there are also metal cable ties. These are usually made from SS304 stainless steel or SS316 acid-resistant stainless steel. The cable ties can be either bare or coated with plastic, which provides additional protection against corrosion.

Self-locking stainless steel cable ties

Metal cable ties, like plastic cable ties, have different designs. Due to the speed of installation, cable ties with ball-lock are most commonly used. By inserting the cable strap into the head, the ball is moved into the wider part of the housing. Attempting to pull the strap out moves the ball into the narrower part of the housing and wedges the cable strap. The downside of this solution is the need for the strap to move back and the sensitivity of the fixing to vibration.

Stainless steel cable ties with fold locking

The new metal cable ties with fold locking do not have the same disadvantages as the cable ties with ball-lock. In the case of fold locking, the cable strap as it passes through the head is blocked by mechanical deformation together with part of the head. The disadvantage of these cable ties is the need for a specialised gun to install the ties.

Cable ties with fixing elements

In order to speed up and facilitate installation, cable ties can be equipped with fixing elements. The fixing elements can be integrated into the cable ties, in which case they are referred to as one-piece fixing ties, or they can function as a separate component to the cable tie. Then it is a two-piece fixing tie. Depending on the type of fixing element, we can distinguish between cable ties with fixings for holes, for screws, for weld studs, for edges, etc.

Fixing elements for cable ties

The primary fixing elements for cable ties are self-adhesive cable tie mounts using different types of adhesive. Another typical fixing element for cable ties are screw cable tie mounts.

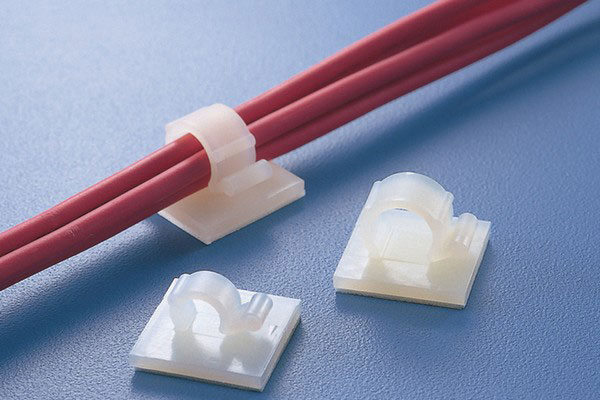

Fixing clips for cables

Cable clips are used to fix cables directly to the substrate without the help of cable ties. These can be self-adhesive, with screw fastening, for pins, screws and edges. A typical example of cable fixings are P-clamps (P-clips) for mounting wires, cables, hoses and pipes. The main advantage of cable clips is that there is no need for cable ties and, for the most part, no need to have specialised tools for installation.

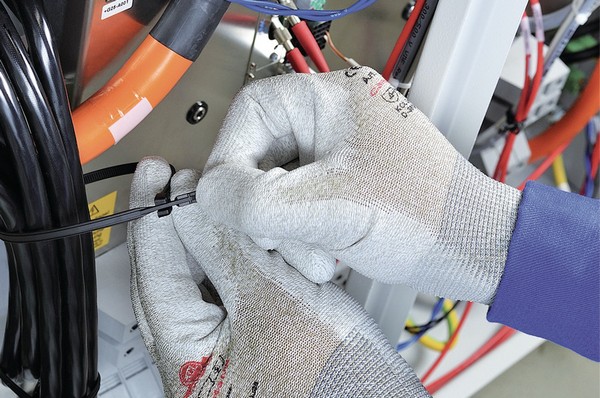

Cable tie gun for tensioning and cutting of cable ties

Cable tie guns are used for the professional installation of cable ties. The cable tie gun allows the cable ties to be tightened with constant, repetitive tension, and after reaching the pre-set tension, it cuts the cable ties flush with the head, leaving no sharp edges. Both manual and pneumatic cable tie guns are available.

A special cable tie gun is used for tightening and cutting metal cable ties. Different tensioning tools should be used depending on the type of metal cable ties.